Loss Factor

Loss factor, or tangent delta, is a measure of how much vibration energy is dissipated through a conversion to heat due to the phenomenon of hysteresis. A loss factor of 0 indicates a perfectly elastic material where the oscillating force of a vibration occurs in-phase (at the same time) with the accompanying deformation of the material. A loss factor of 1 indicates a perfectly viscous material where the force and deformation are exactly 90 degrees out of phase resulting in total dissipation of vibration energy to heat.

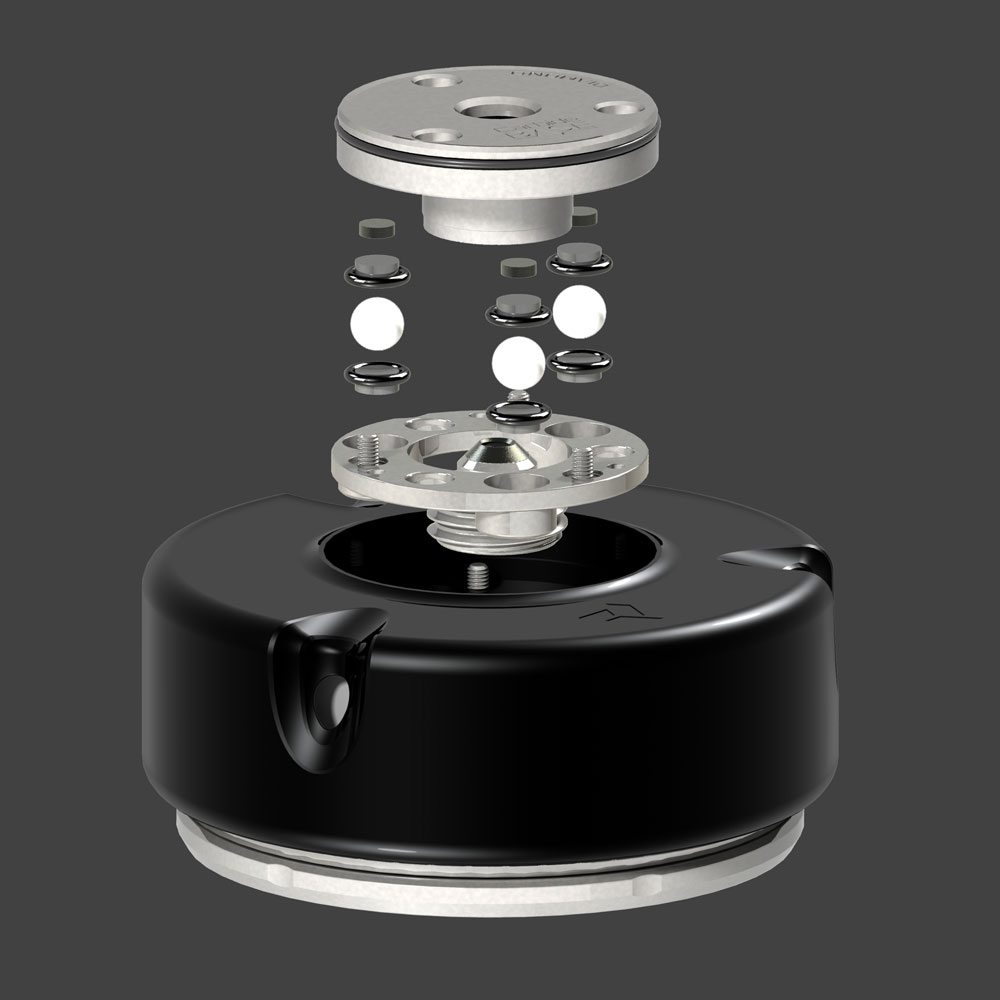

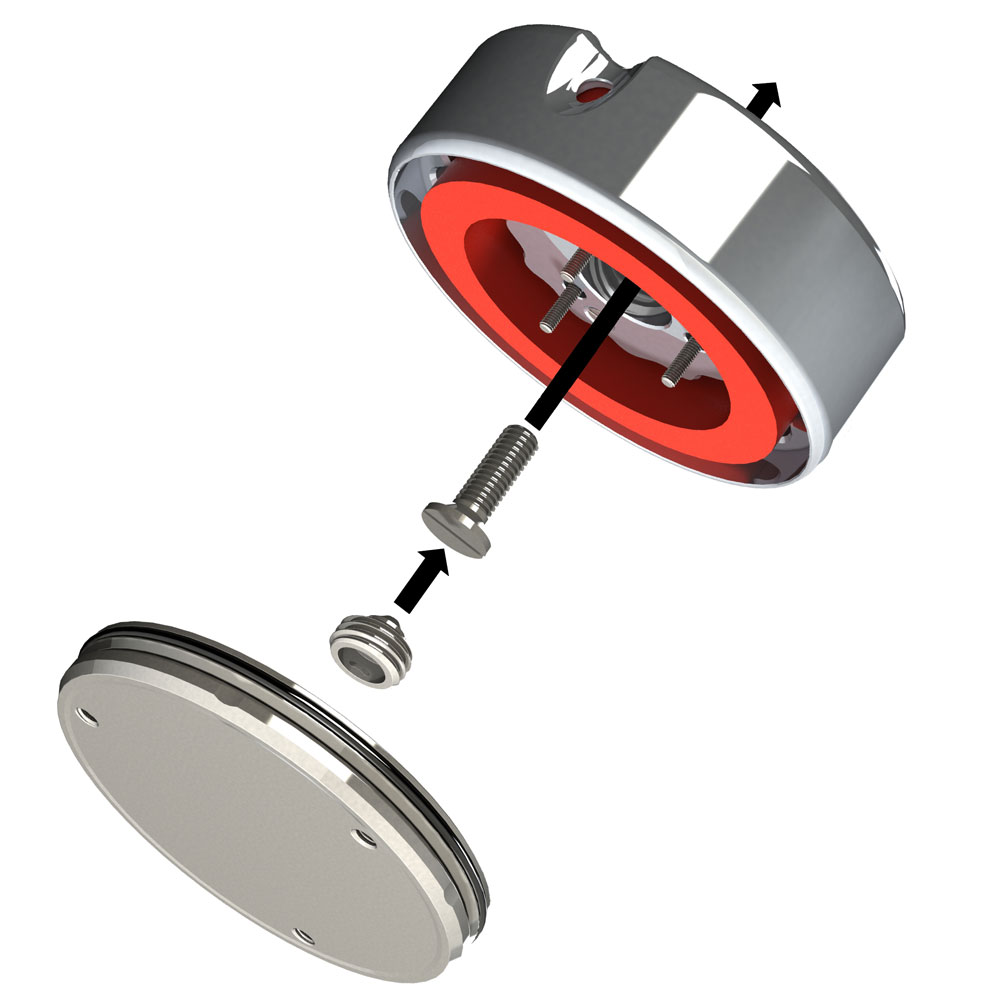

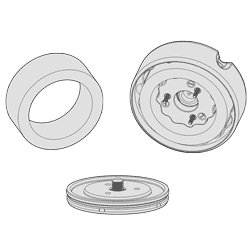

The viscoelastic materials utilized in Carbide Base footers are engineered to have an exceptionally high loss factor over a wide frequency range. The larger ViscoRings™ in the Carbide Base footer have the highest loss factors, followed closely by the smaller Micro ViscoRings™ in the Carbide Base Micro footer.

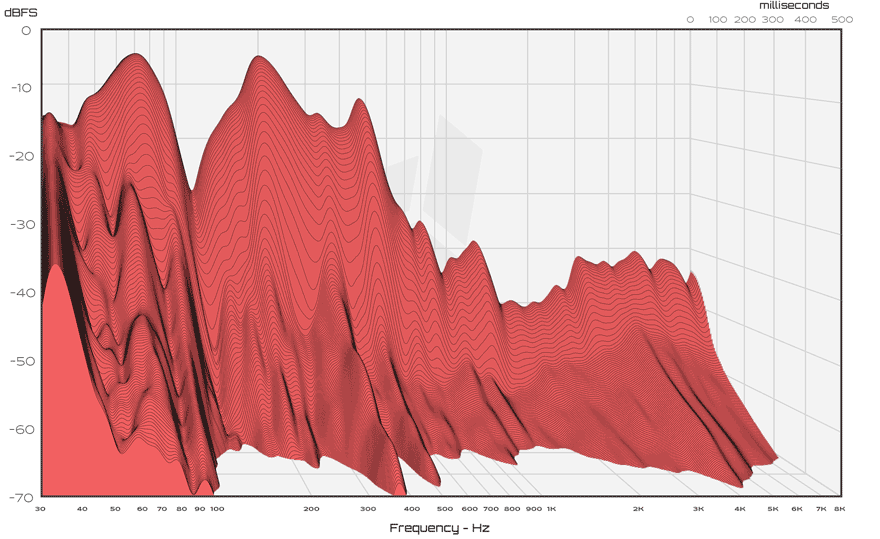

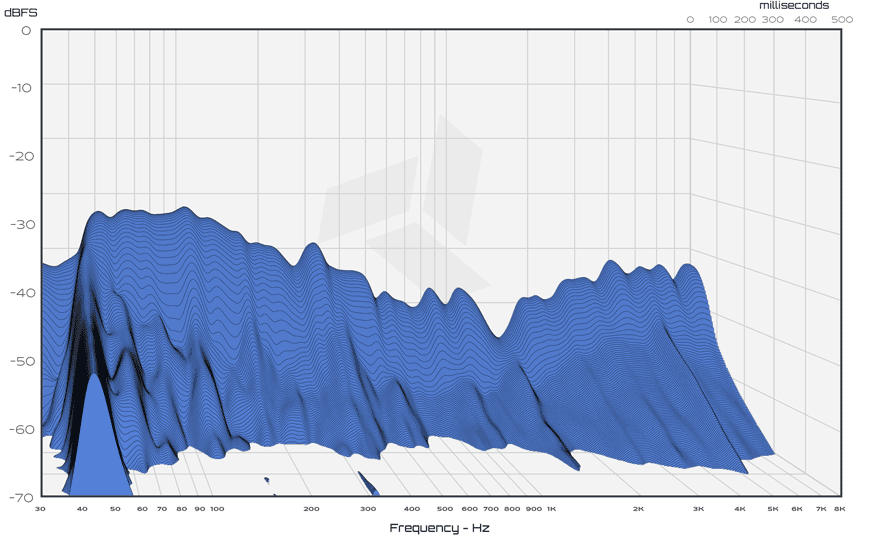

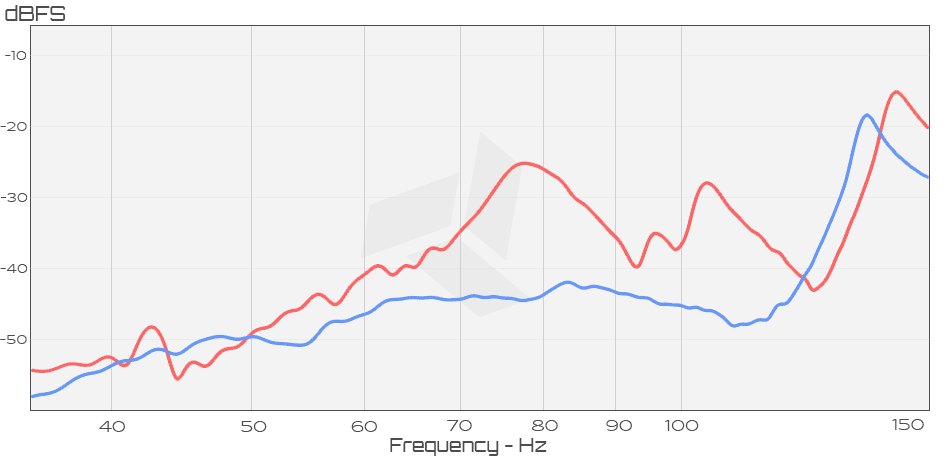

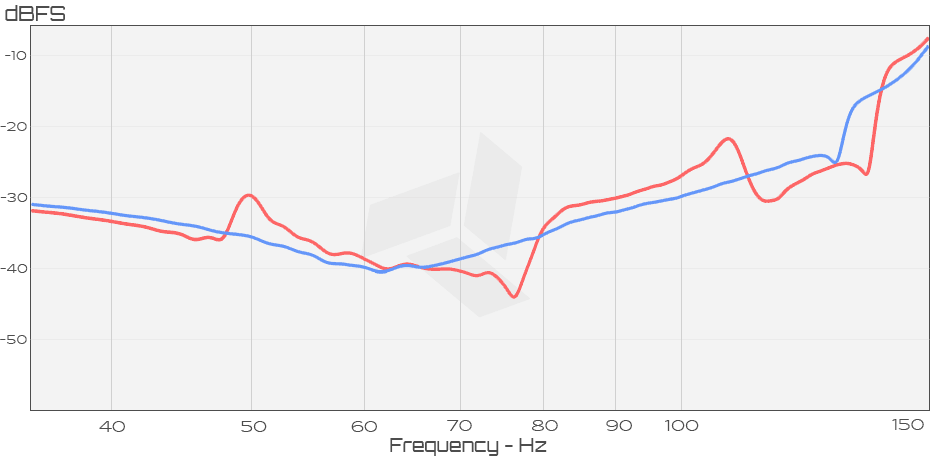

The vibration dissipation ability of a Carbide Base footer is significant enough to measurably subdue resonances in equipment being supported. The graphs below show low frequency vibrations in the panels of a test loudspeaker enclosure as measured using a calibrated accelerometer. Dips and spikes in panel acceleration indicating resonances are effectively damped when the same measurement is taken with Carbide Base footers placed under the loudspeaker.