Transmission Path Evasion

While designing our Carbide Base Diamond footer, we conducted experiments to quantify the benefits of transmission path evasion. This is a concept to improve the performance of vibration isolator designs which utilize ball bearings rolling in curved bearing raceways.

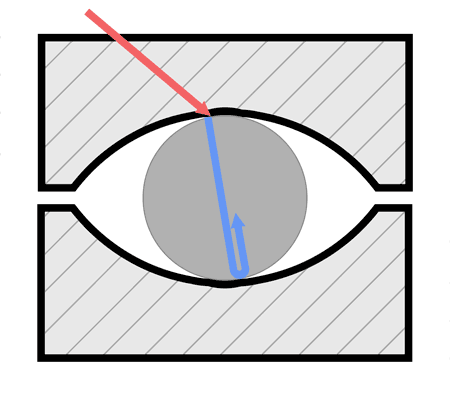

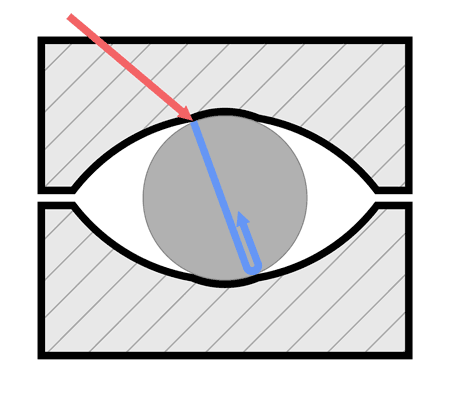

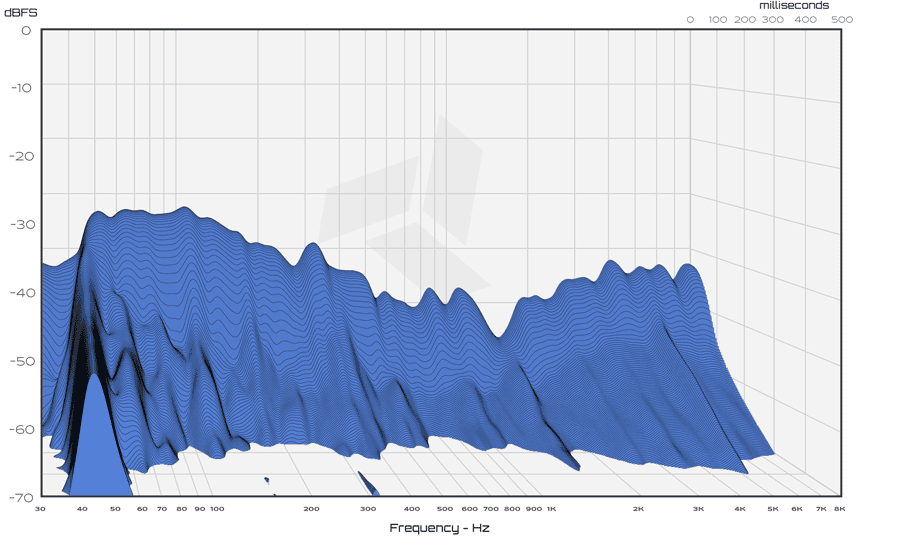

First, an explanation of transmission path evasion. When a ball bearing rolling in a curved bearing raceway encounters a vibration, vibration energy in the form of a sound wave will enter the bearing. The sound wave enters from a point on the bearing that is in contact with the vibrating raceway at that given instant. After the sound wave traverses across the bearing it will reach the other side and much of the energy will reflect back to the point of entry.

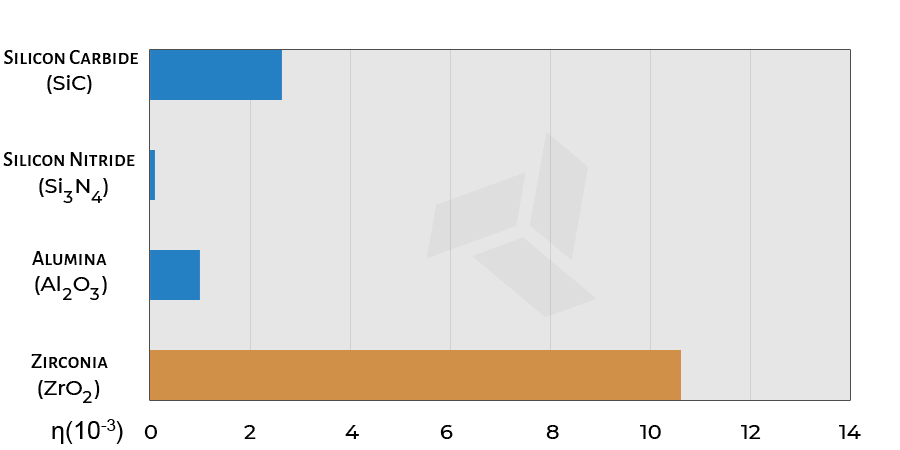

A bearing rolling in a theoretically perfect curved raceway will be in constant unimpeded motion when subjected to vibrations. Thus, by the time the sound wave reflects back to the point of entry, the bearing will likely have rotated away from its position at the moment that the sound wave entered. With the original point of entry no longer in contact with the raceway surface, the exit path for the reflected sound wave is severed. The sound wave will then refract and disperse internally within the bearing and eventually dissipate as heat.

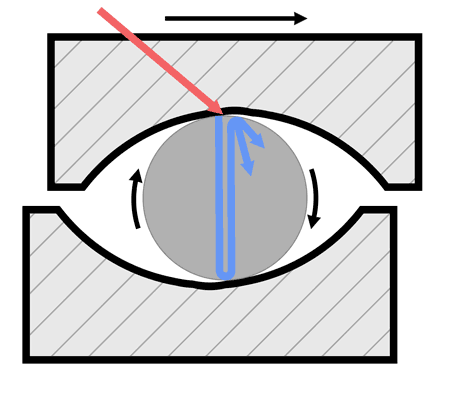

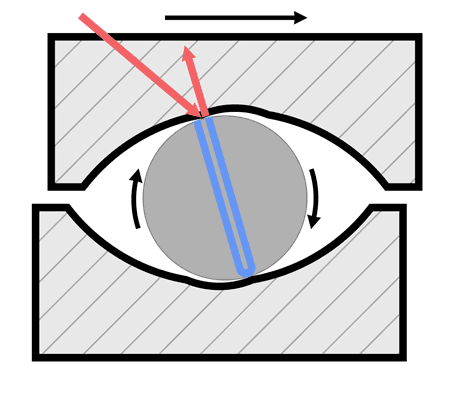

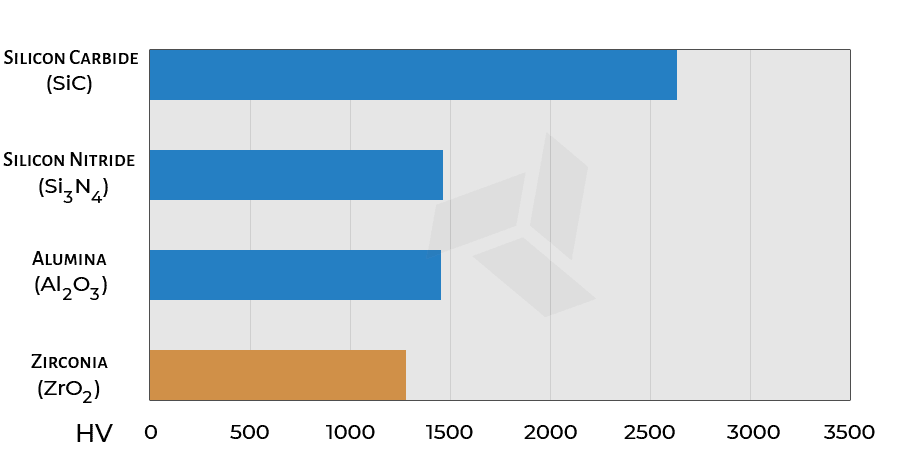

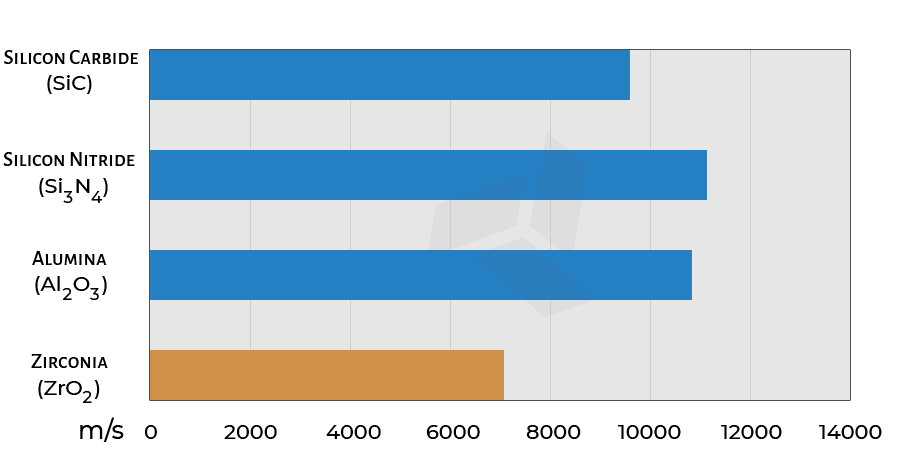

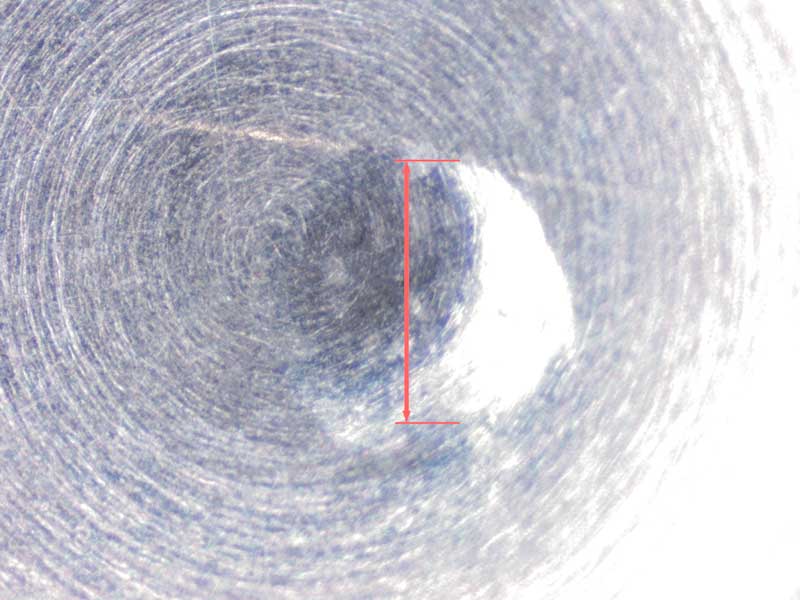

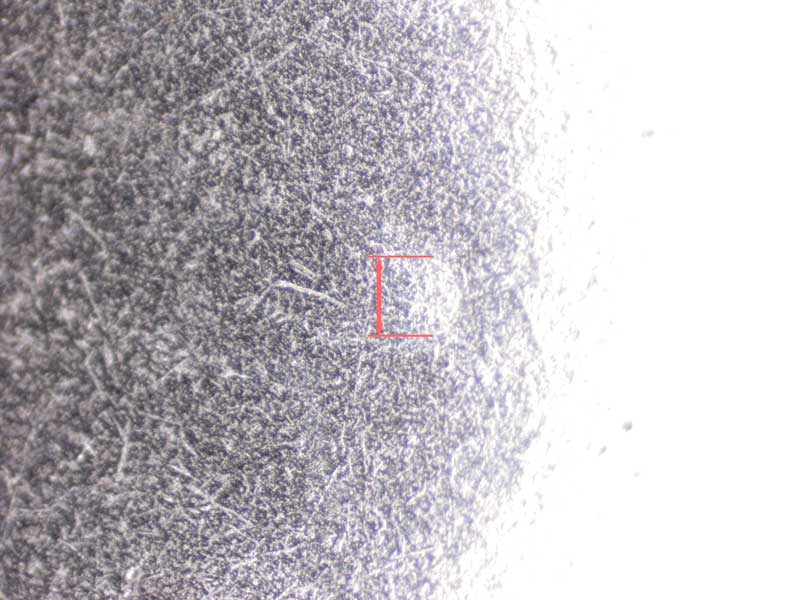

A bearing raceway is never perfect however. A ball bearing focuses pressure into an infinitely small point. This pressure will inevitably cause an indentation in the bearing raceway when a sufficient load is applied. The diameter of the indentation is dependent on the payload weight, the radius of the bearing, the radius of curvature of the raceway, and the hardness of the raceway material[1].

Adverse Effects of a Raceway Indentation

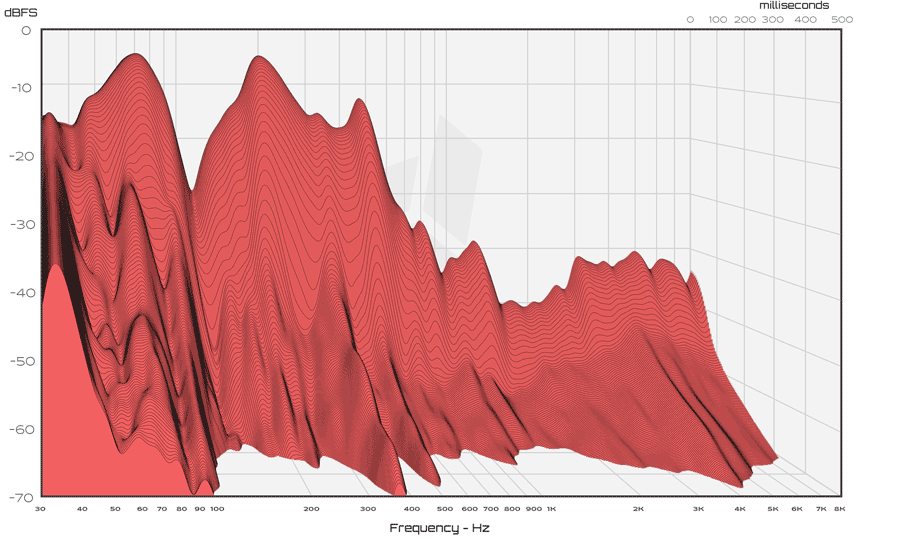

The presence of an indentation in the bearing raceway adversely affects vibration isolation performance in 2 ways:

- It increases stiction meaning that the bearing will require more force to set in motion within the raceway. This reduces the ability for the device to respond to and therefore isolate vibrations with small amplitudes.

- The bearing will remain in sustained contact with the indentation throughout a portion of its motion within the raceway. If the time spent in contact with the indentation is longer than the time it takes for a sound wave to traverse across the bearing and back again, the reflected sound wave will be able to exit back through the the entry contact location.