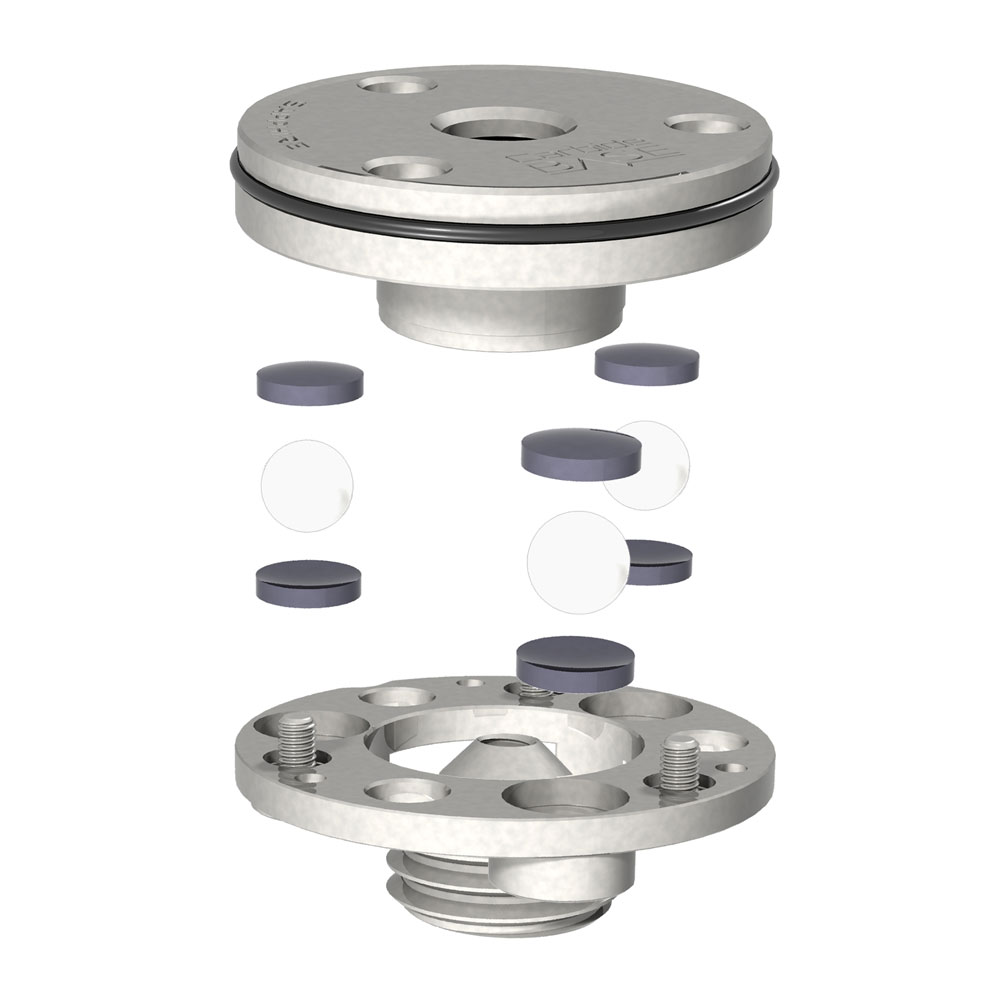

Carbide Base Inserts

A Carbide Base Insert can replace the stainless steel top center section of either Carbide Base footer to add an additional vibration isolation stage. A Nano Insert can be installed into the center threaded hole of our footers as an alternate way to improve isolation performance.

These inserts are special vibration isolators which utilize ceramic ball bearings rolling in raceways coated using Physical Vapor Deposition (PVD) processes. Carefully designed geometries combined with extreme material hardness allow leveraging of Transmission Path Evasion to enhance filtering of micro vibrations. The inserts are available in 2 versions: Sapphire and Diamond.

Sapphire

The Sapphire inserts utilize bearing raceways formed from a high-carbon steel which is then heat treated to increase hardness. After 8 stages of polishing, the bearing raceways are then coated with Diamond-Like Carbon (DLC) combined with a special metal using a PVD process. The raceways are then cryogenically tempered to relieve internal stresses and improve toughness.

Diamond

The Diamond inserts utilize raceways machined from solid ceramic with around twice the hardness of hardened steel. The polished bearing raceways are then coated with PVD Diamond. Our TwinDamp™ high-damping alloy is used in locations above the raceways to further improve performance.