TwinDamp™: Improving the Damping Capacity of Manganese-Copper

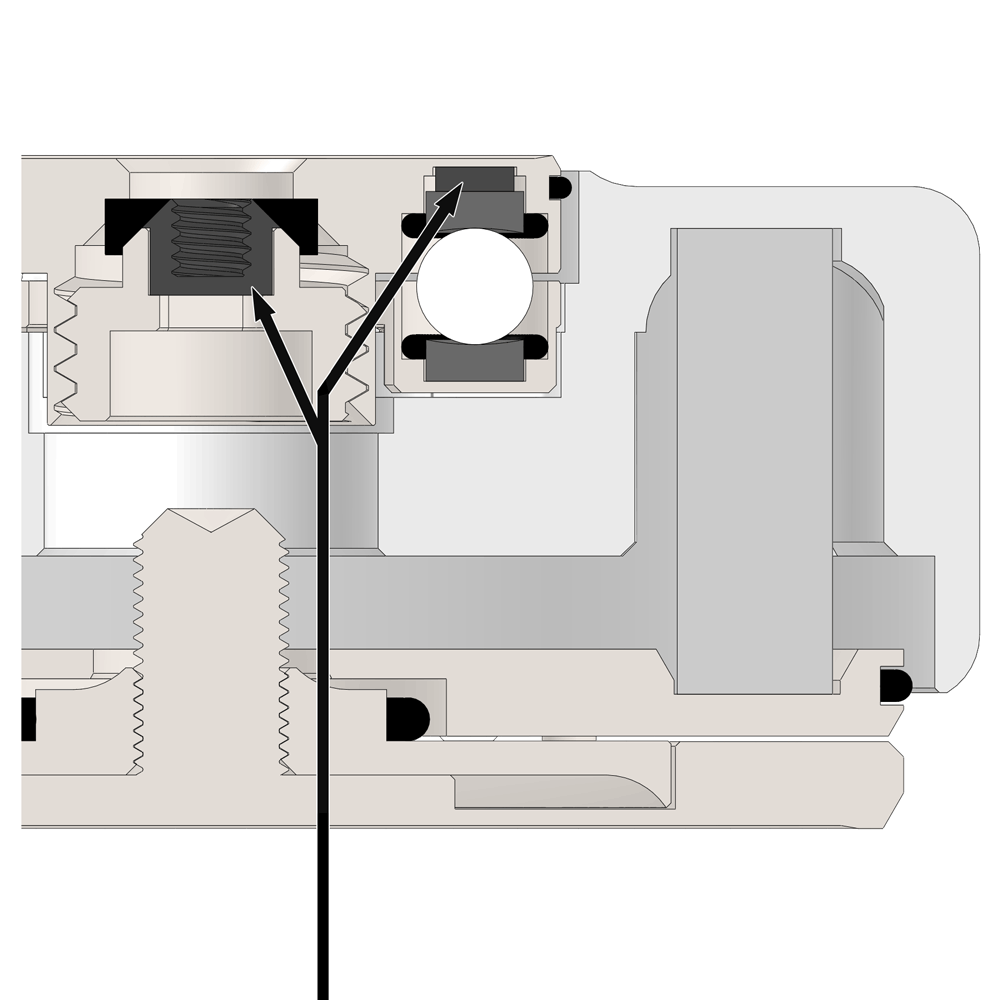

While designing the Diamond Insert for our Carbide Base footer we sought to utilize a high-damping metal alloy to improve isolation performance. Through research and testing we developed TwinDamp™ – a temperature treated manganese-copper twin crystal metal alloy with exceptional damping properties from 0.01 Hz to 10 MHz .

When manganese-copper alloys are subjected to vibrations, the strain caused by the movement of martensite twins or by the mutual movement between the twin boundaries and martensitic phase boundaries relaxes the stress and dissipates the vibration energy[1]. In other words, small movements between boundaries within the material allow it to effectively dissipate vibrations through a conversion into heat.

Manganese-copper alloys are among the highest damping metal alloys in existence having a damping capacity over 10 times greater than copper[2]. While the damping capacity of these alloys is much less than the elastomers utilized in our ViscoRing™, they have the distinct benefit that as a rigid metal they better maintain their form under load.

Improving Manganese-Copper with Temperature Treatments

It is known that manganese-copper alloys are sensitive to temperature treatments. Sustained exposure to high temperatures also known metal aging can initially improve the damping and strength properties of these alloys. This is due to the enhancement of manganese-rich regions within the material. Over aging can begin to compromise damping capacity however, so balanced treatment temperature and duration is needed for optimal results[3].

A gradual exposure to cryogenic temperatures can also enhance the crystalline structure within metals. This cryogenic tempering process can impart desirable sonic improvements to manganese-copper alloys.

Through experimentation we developed an effective temperature treatment process for the manganese-copper alloy that we use. Our distinct process involves multiple stages of both hot and cold treatments. The treatments are performed over a two day period to improve the damping and sonic performance of this alloy.

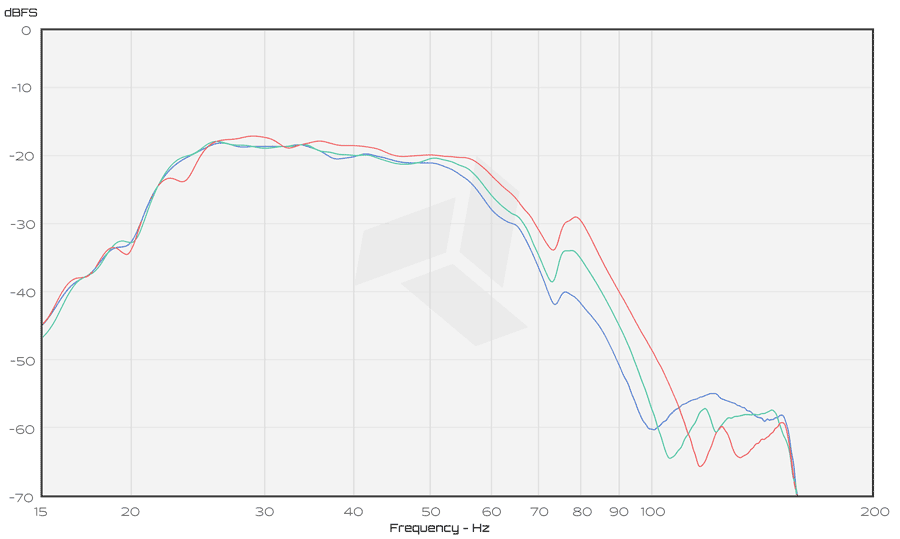

Vibration Amplitude for All Spikes

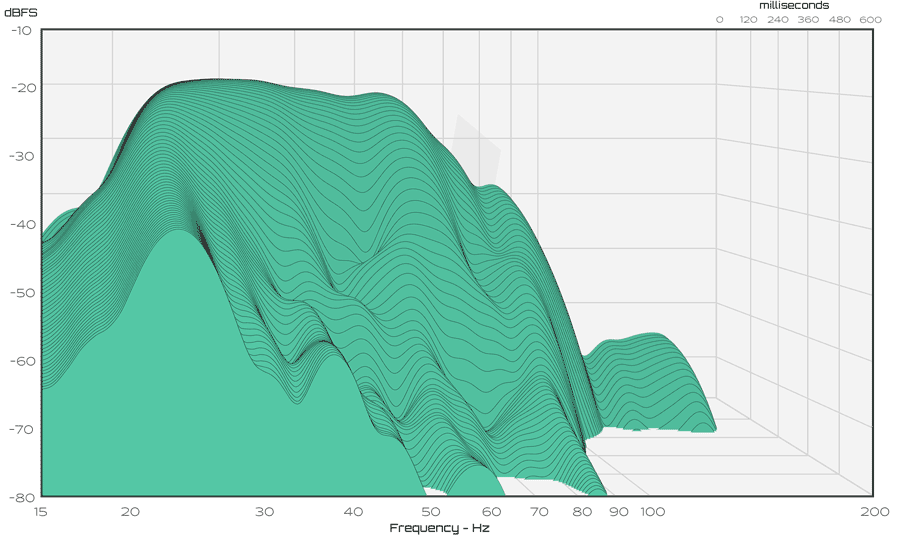

Stainless Steel Waterfall

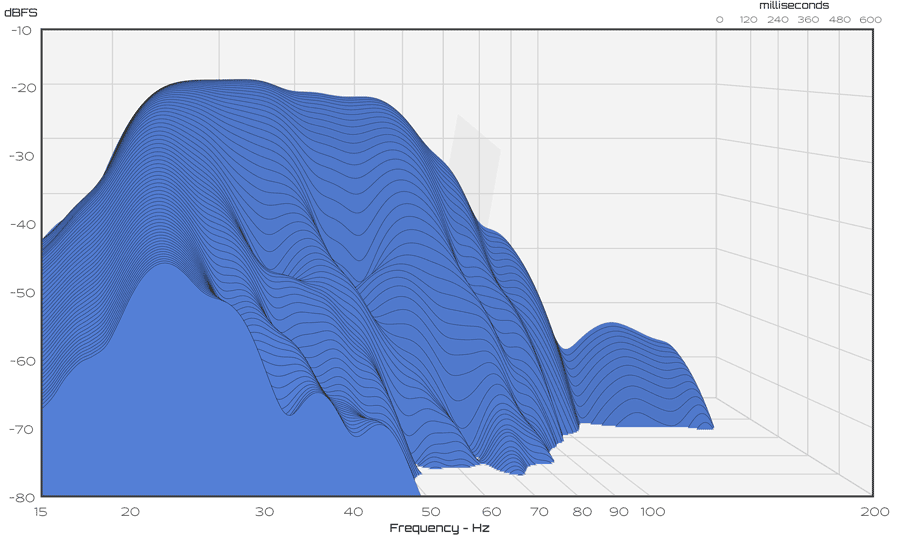

Manganese-Copper Waterfall

Conclusion

The manganese-copper spikes provided a subtle but measurable improvement in vibration attenuation compared to the stainless steel spikes. The TwinDamp™ spikes provided even more attenuation than the manganese-copper validating the effectiveness of our temperature treatment process. The improvements were most significant around the subwoofer cabinet resonance at 80 Hz. Both the manganese-copper and TwinDamp™ also showed increased damping capacity as evidenced by the smoothing of the vibration amplitude traces and faster vibration decay in the waterfall graphs.

References

[1] Lu F-S, Wu B, Zhang J-F, Li P and Zhao D-L 2016 Microstructure and damping properties of MnCuNiFeCe alloy Rare Met. 35 615–9

[2] Zhang, J., Perez, R. J., and Lavernia, E. J., “Documentation of damping capacity of metallic, ceramic and metal-matrix composite materials”, Journal of Materials Science, vol. 28, no. 9, pp. 2395–2404, 1993. doi:10.1007/BF01151671

[3] Ke, T. S., Wang, L. T., & Yi, H. C. (1987). Internal friction in manganese-copper and manganese-copper-aluminium alloys. Le Journal de Physique Colloques, 48(C8), C8-559.